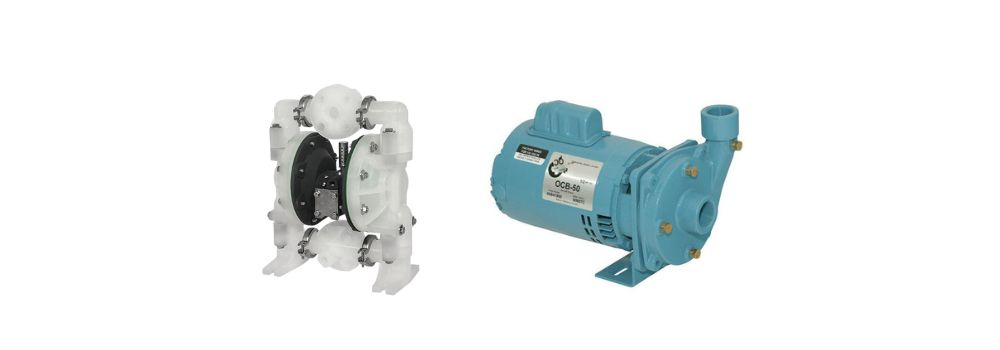

Diaphragm Pumps vs. Centrifugal Pumps: Which One to Choose for Your Application

When it comes to pumping applications, selecting the right pump for the job can be a challenging task. Diaphragm pumps and centrifugal pumps are two popular types of pumps used in various industries, and both have their advantages and disadvantages. In this article, we will explore the differences between diaphragm pumps and centrifugal pumps and help you decide which one is best suited for your application.

What are Diaphragm Pumps?

Diaphragm pumps are positive displacement pumps that move fluids by using a flexible diaphragm to create a vacuum or pressure in a chamber. They are also known as membrane pumps or air-operated double-diaphragm pumps (AODD). Diaphragm pumps are widely used in the chemical, pharmaceutical, food and beverage, and mining industries.

Advantages of Diaphragm Pumps:

-

Can handle viscous and abrasive fluids: Diaphragm pumps are capable of handling a wide range of fluids, including viscous, abrasive, and shear-sensitive fluids.

-

Self-priming: Diaphragm pumps can self-prime, which means they can start pumping without the need for external priming.

-

Can handle solids: Diaphragm pumps are capable of handling fluids that contain small solids or particles without clogging.

-

Good suction lift: Diaphragm pumps can create suction lifts up to 20 feet, making them ideal for applications where fluids need to be lifted from a lower level.

What are Centrifugal Pumps?

Centrifugal pumps are dynamic pumps that use an impeller to move fluids by converting rotational energy into kinetic energy. They are commonly used in the oil and gas, water treatment, and HVAC industries.

Advantages of Centrifugal Pumps:

-

High flow rate: Centrifugal pumps can handle large volumes of fluids, making them ideal for applications where high flow rates are required.

-

Low maintenance: Centrifugal pumps have few moving parts, which means they require less maintenance compared to other types of pumps.

-

Cost-effective: Centrifugal pumps are relatively inexpensive compared to other types of pumps.

-

Energy-efficient: Centrifugal pumps are energy-efficient and can save on energy costs.

Diaphragm Pumps vs. Centrifugal Pumps:

-

Flow rate: Diaphragm pumps have a lower flow rate compared to centrifugal pumps. They are better suited for low flow rate applications, while centrifugal pumps are better suited for high flow rate applications.

-

Fluid type: Diaphragm pumps are better suited for viscous, abrasive, and shear-sensitive fluids, while centrifugal pumps are better suited for clean fluids with low viscosity.

-

Maintenance: Diaphragm pumps have more moving parts compared to centrifugal pumps, which means they require more maintenance.

-

Cost: Diaphragm pumps are more expensive compared to centrifugal pumps.

-

Efficiency: Centrifugal pumps are more energy-efficient compared to diaphragm pumps.

Conclusion:

Choosing the right pump for your application depends on several factors, including the fluid type, flow rate, and maintenance requirements. Diaphragm pumps are better suited for low flow rate applications that involve viscous, abrasive, and shear-sensitive fluids. Centrifugal pumps are better suited for high flow rate applications that involve clean fluids with low viscosity. Both types of pumps have their advantages and disadvantages, and selecting the right one for your application can make all the difference. Consider consulting with a pump specialist to determine the best pump for your specific needs.